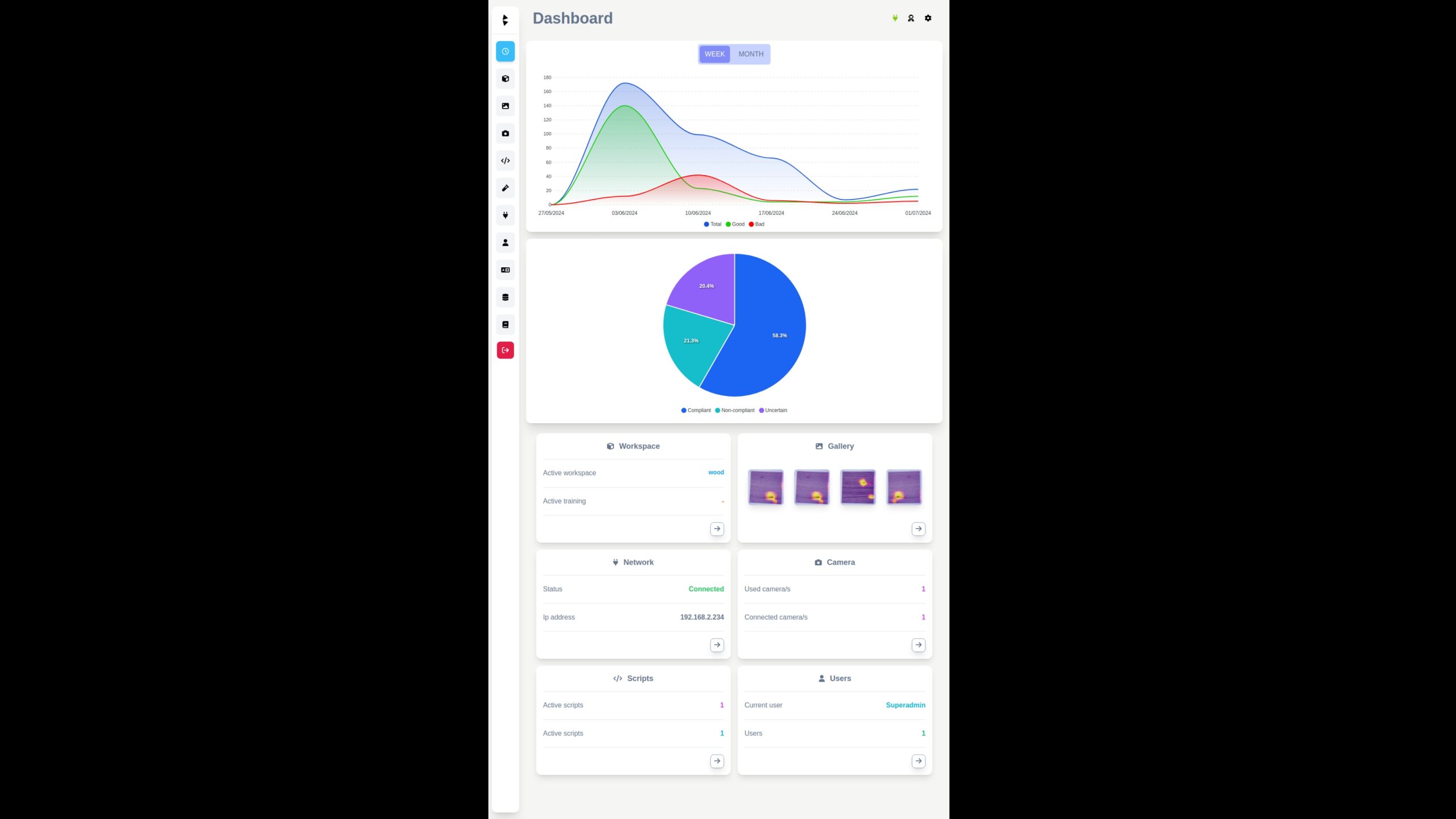

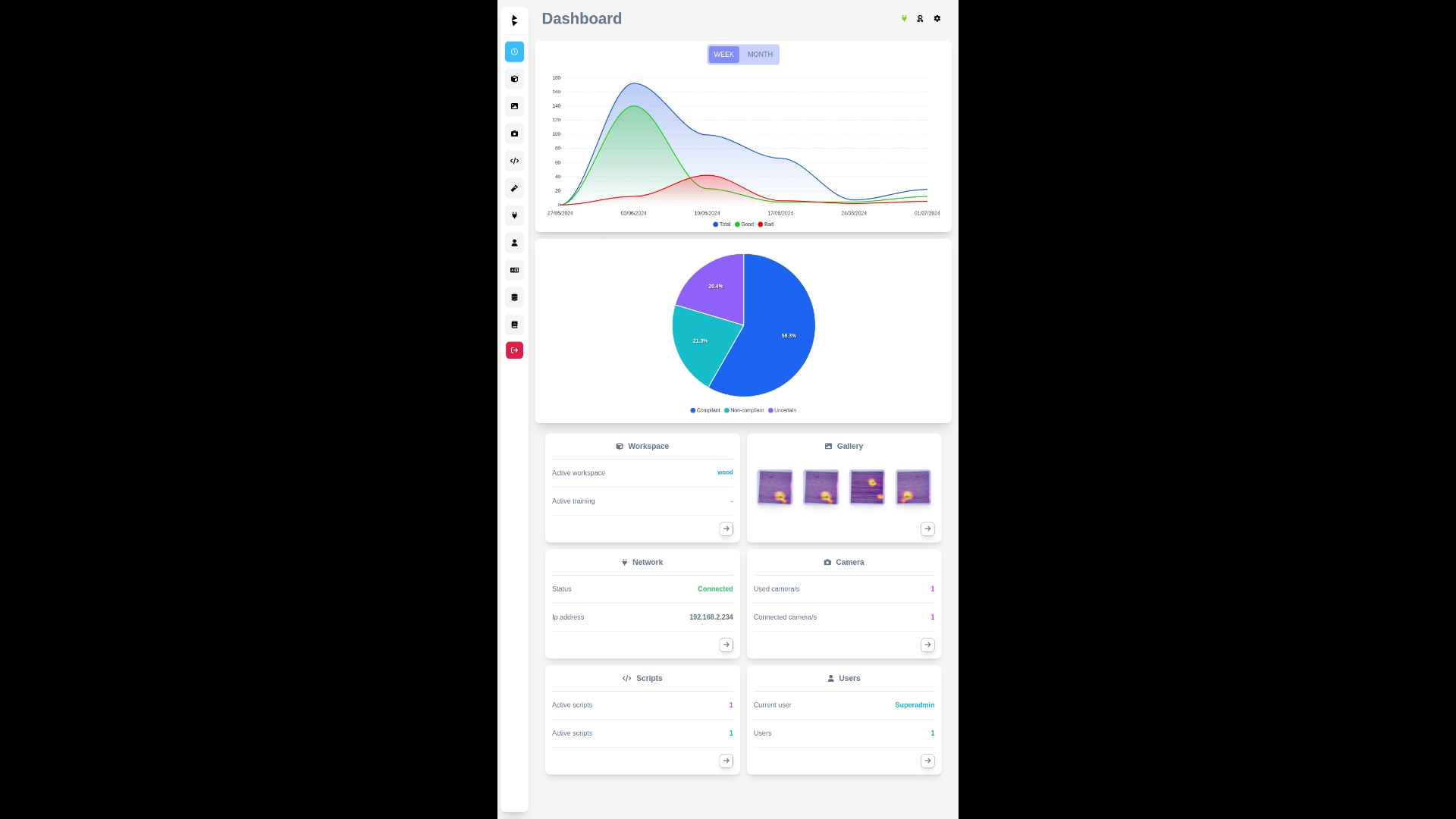

BIION-D is the next-generation machine-vision solution for industrial visual inspection and defect detection, engineered to improve product quality and reduce production waste.

- It’s powerful because it applies deep learning (AI) to analyze images and make pass/fail decisions using advanced algorithms trained on your data.

- It’s complete because it was developed around the needs of small and mid-sized manufacturers (SMEs): a simple hardware-and-software system, already integrated with common factory ecosystems, and offered at a competitive price.

Moreover, compared with other industrial vision systems on the market, BIION-D is:

- Integrated with factory protocols

Ready to plug into existing plant infrastructure - Trainable with a small set of compliant images

No need to collect and label defective samples, reducing operator workload - Easy to configure and interpret

No experts required to understand real-time analysis results

This solution represents an opportunity for

IT Partners

ICT GROUPS

IT CONSULTING

SYSTEM INTEGRATORS

COMPANIES IN THE ROBOTICS AND IoT SECTORS

DISTRIBUTORS

Industrial manufacturers

MANUFACTURERS OF MACHINES AND EQUIPMENT

(OEM – Original Equipment Manufacturer)

MANUFACTURERS OF TOOLS, WOOD COMPONENTS, TEXTILES, LENSES, ETC.

click the corresponding button to learn more

Manufacturing landscape

Companies are increasing their annual investment in Artificial Intelligence and automation systems by 30% to optimize production processes, reduce downtime, and improve product quality.

One of the main barriers to innovation is the shortage of qualified personnel, which limits the ability to respond quickly to market demands, where adaptability and specialization are critical to maintaining a competitive edge.

AI can most effectively address this skills gap in quality control: human operators, often working repetitive and exhausting shifts, can be supported – or even replaced – by vision systems that replicate human capabilities, speeding up inspection while maintaining high performance levels.

*Source: Rockwell Automation, 9th “State of Smart Manufacturing” report.Improving industrial quality ranks first among technological investments – an area where AI can make a decisive difference in staying competitive.

Vision Systems for Quality Control

Vision systems for quality control are essential to ensure products meet the market’s high standards.

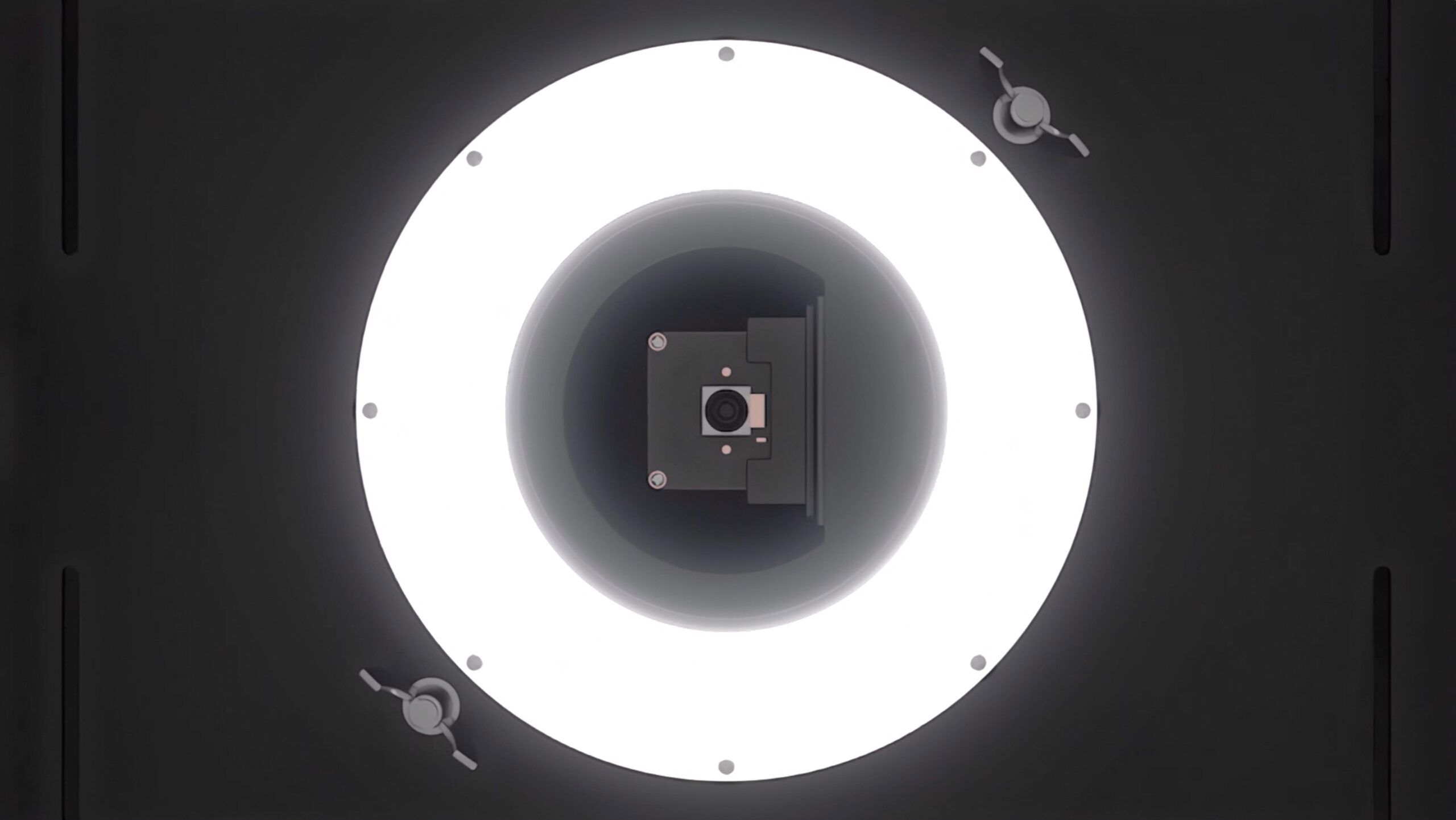

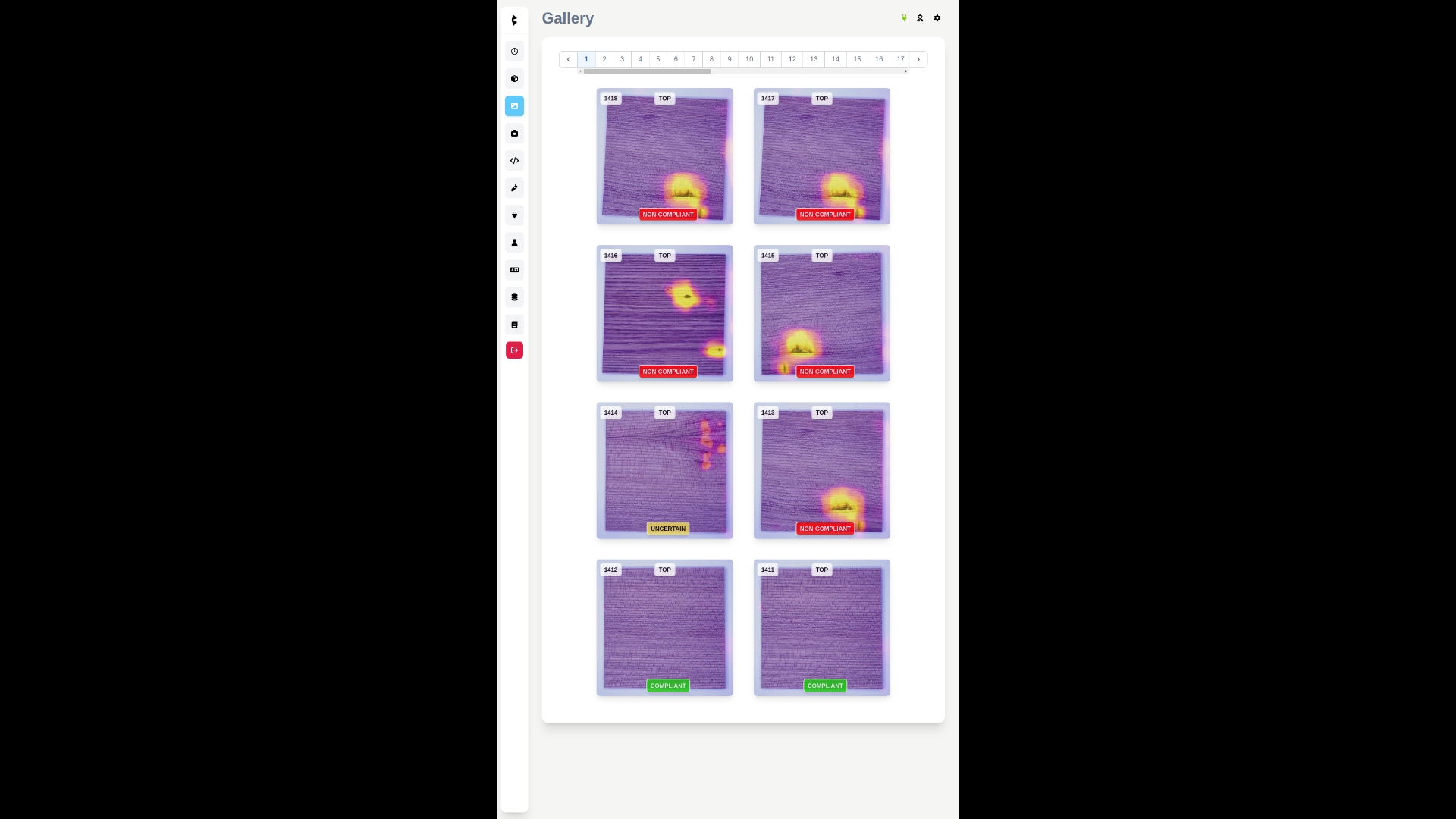

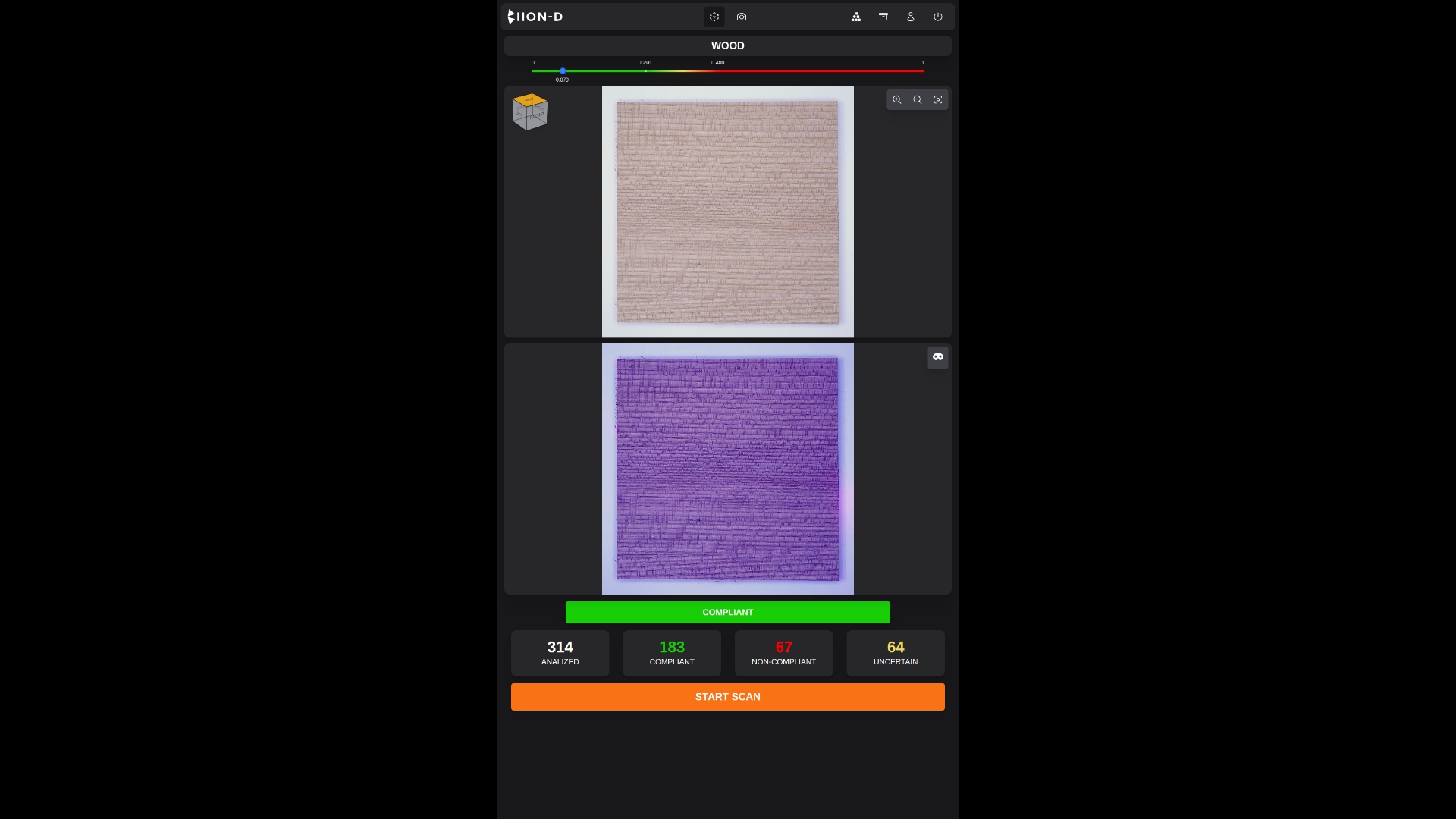

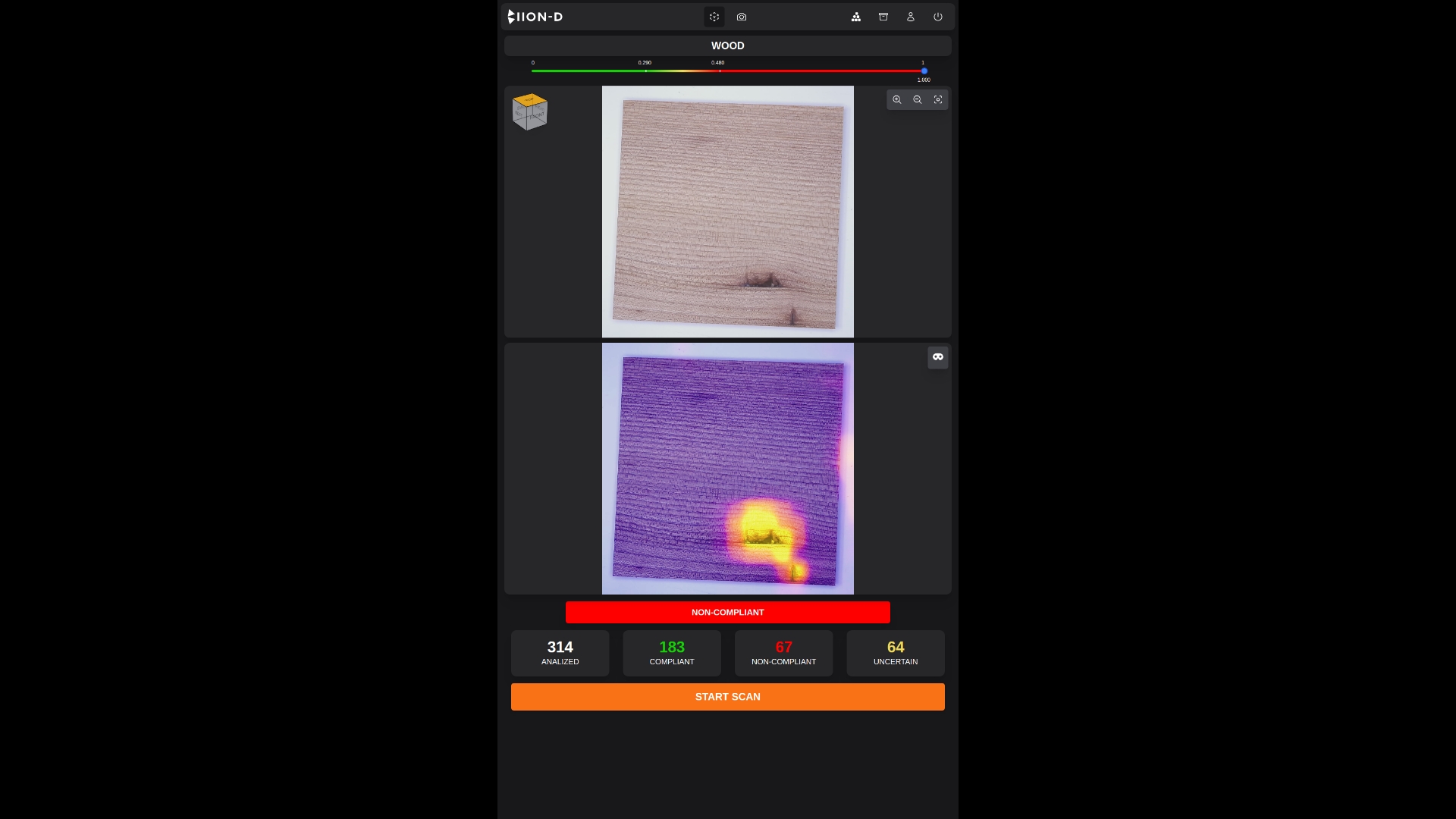

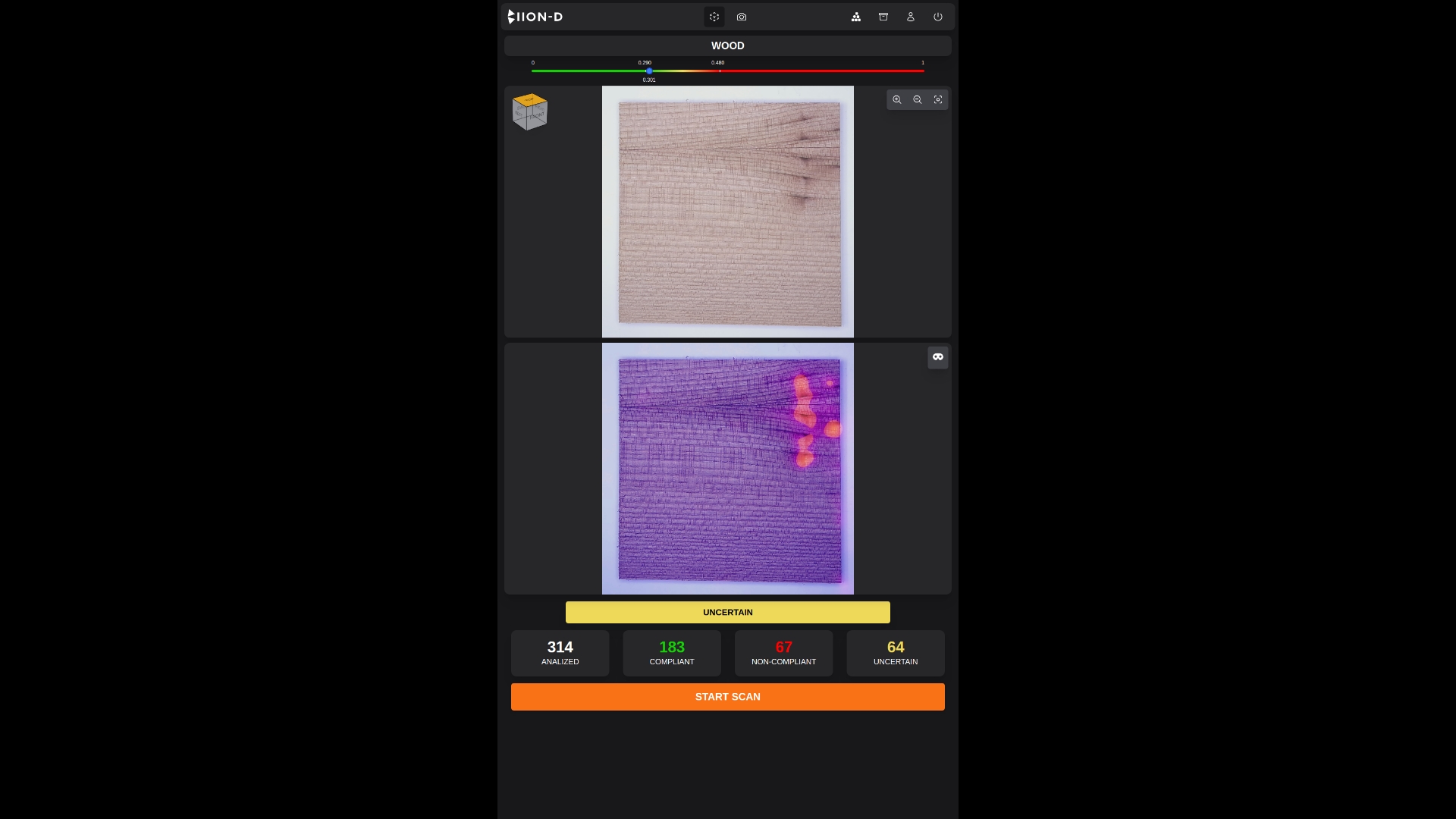

Using high-resolution cameras and advanced image-processing software, they inspect parts in real time on the production line and interface with factory equipment (e.g., PLCs) to detect defects and imperfections. The speed and accuracy of these inspections reduce waste, lower production costs, and improve operational efficiency.

Why Use Deep Learning for Quality Control

Using deep learning for image-based quality control is a major step forward in visual inspection.

Deep neural networks (AI) can be trained to detect even the smallest defects that might escape the human eye, improving inspection accuracy and offering greater flexibility. The result is a more efficient quality-control process that sustains high production standards in dynamic industrial environments.

A deep-learning vision system for quality control can match the performance of even the most experienced human operator while delivering 24/7 consistency and reliability. The outcome is improved quality and greater operational efficiency.

Deep learning–based vision systems for quality control, like BIION-D, can make a real difference for:

Manufacturers of machines and equipment

Industrial manufacturers

Find out how to get BIION-D: click the corresponding button!

If you are:

IT Partners

ICT GROUPS

IT CONSULTING

SYSTEM INTEGRATORS

COMPANIES IN THE ROBOTICS AND IoT SECTORS

DISTRIBUTORS

Industrial manufacturers

MANUFACTURERS OF MACHINES AND EQUIPMENT

(OEM – Original Equipment Manufacturer)

MANUFACTURERS OF TOOLS, WOOD COMPONENTS, TEXTILES, LENSES, ETC.

About Us

Visio…naries? Maybe. We pride ourselves on being on point – fully aware of the opportunities we can offer manufacturing SMEs to help them stay competitive.

Visiofy is a team of IT professionals with a sharp business focus, specializing in the industrial sector for over 15 years, and with a healthy obsession for everything related to artificial intelligence.

Solution

BIION-D was born from a simple idea, backed by market research: AI can truly make a difference by solving complex problems and supporting people in managing repetitive, exhausting processes.

Business Model

Our growth strategy involves selling BIION-D through IT partners. We believe strong relationships –between supplier and client, and between partner and manufacturer– should be expanded and encouraged.

With BIION-D, we allow IT partners to address a real industry need by expanding their commercial offering with a turnkey solution that is both powerful and cost-competitive.